The Revolution of Jewelry Manufacturing: 3D Graphics and Wax Printing

In the modern world of jewelry making, the industry is undergoing a groundbreaking transformation through the use of 3D graphics and wax printing. These innovative technologies enable designers and jewelers to create stunning pieces of jewelry with the highest precision and creativity. In this article, you will learn how 3D graphics and wax printing are revolutionizing jewelry manufacturing and the benefits they offer.

In the modern world of jewelry manufacturing, the industry is undergoing a groundbreaking transformation through the use of 3D graphics and wax printing. These innovative technologies allow designers and jewelers to create stunning pieces of jewelry with the utmost precision and creativity. This article explores how 3D graphics and wax printing are revolutionizing jewelry production and the advantages they bring.

3D graphics have established themselves as an indispensable tool for jewelry designers. Advanced software allows designers to create detailed and realistic models of their designs. These digital designs enable visualization of complex geometries and intricate details before transitioning to physical production. The use of 3D graphics offers several advantages:

Precision and Accuracy: Digital models are extremely precise, allowing for meticulous planning of every detail of the jewelry piece.

Flexibility in the Design Process: Changes and adjustments can be made quickly and easily, making the design process more efficient.

Virtual Prototypes: Designers can create and present virtual prototypes before moving into production, saving time and costs.

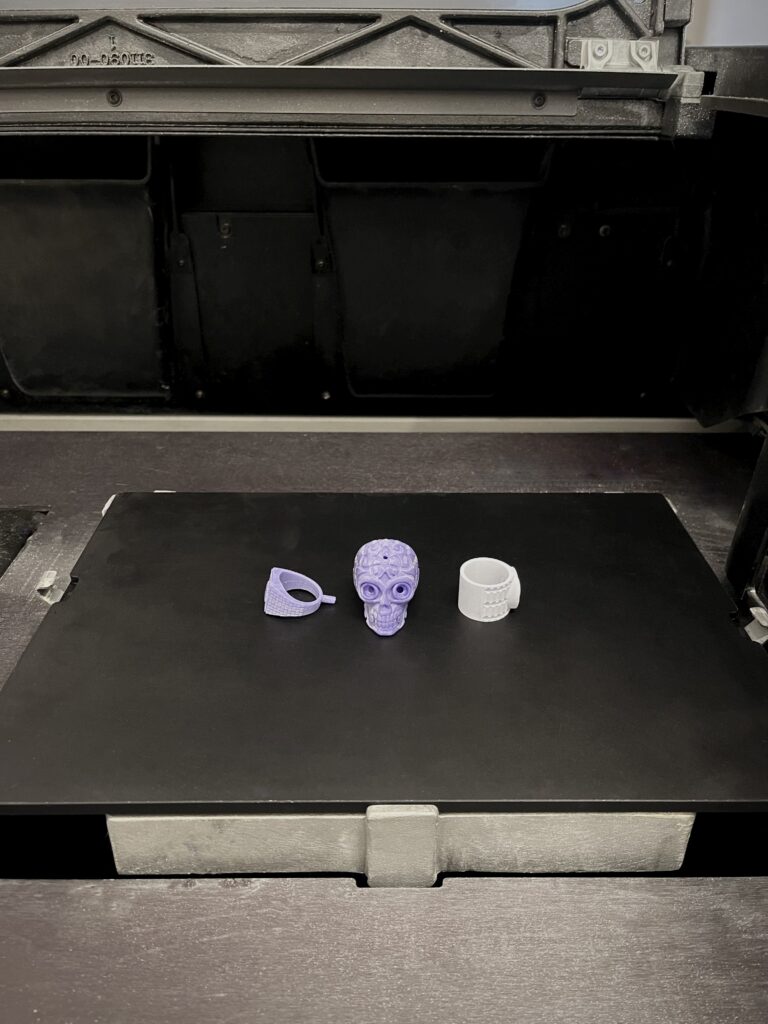

Wax printing: The next crucial step after creating the 3D model. In this process, the digital model is transformed into a physical wax model, which serves as a template for the final piece of jewelry. Wax printing offers numerous advantages:

High Detail Accuracy: Wax printers can reproduce the finest details and intricate designs accurately, which is challenging to achieve with traditional methods.

Time and Cost Savings: Wax printing significantly reduces production time and material waste, leading to cost savings.

Diverse Design Options: Wax printing allows for nearly limitless design possibilities, from delicate patterns to complex structures.

The entire process of jewelry manufacturing using 3D graphics and wax printing involves several steps:

1. Design and Modeling: The designer creates a detailed 3D model of the jewelry piece using specialized software.

2. Wax Printing: The digital model is converted into a physical wax model. This wax model serves as the template for the casting mold.

3. Molding and Casting: The wax model is embedded in a casting mold and melted away. The desired precious metal is then poured into the resulting mold.

4. Finishing: The cast jewelry piece is removed from the mold, cleaned, and meticulously polished to achieve its final finish.

The integration of 3D graphics and wax printing in jewelry manufacturing offers significant benefits for both customers and jewelers:

- Customized Adjustments: Customers can have personalized jewelry pieces designed according to their wishes and preferences.

- Faster Delivery Times: The efficiency of the process significantly reduces production time, leading to quicker delivery times.

- Higher Quality: The precision and detail accuracy of the technology ensure jewelry pieces of the highest quality.

Contact us today via our contact form and discover the solutions we can offer you!